Iindaba zeshishini

-

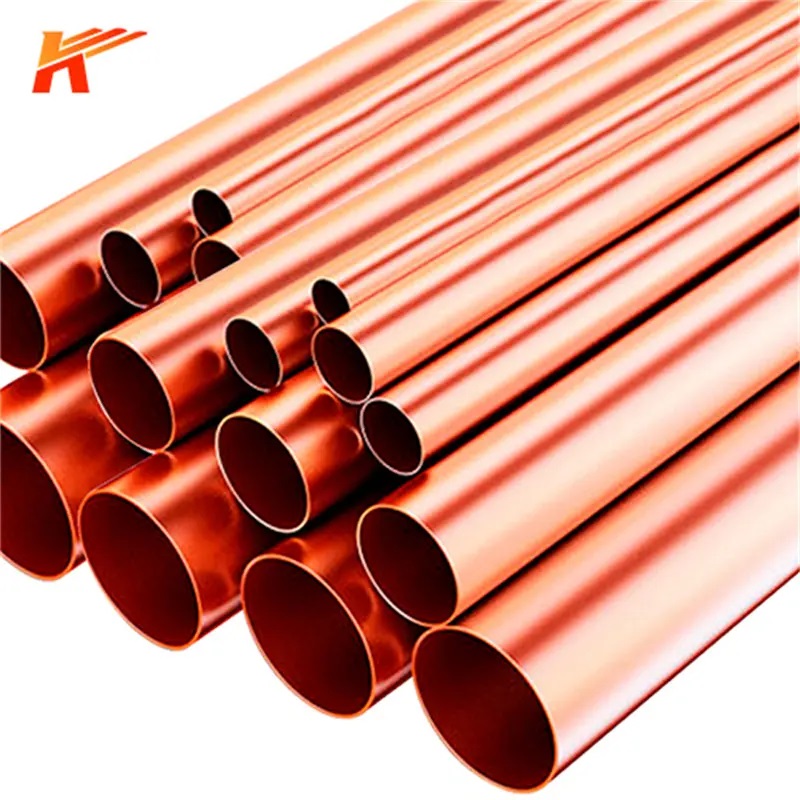

Inzuzo ityhubhu yobhedu

1. Ikhuselekile kwaye inokwethenjelwa: ityhubhu yethusi idibanisa iingenelo zombhobho wensimbi kunye nombhobho ongeyena-metal.Kunzima kunombhobho weplastiki, unamandla aphezulu esinyithi ngokubanzi (amandla ombhobho wobhedu otsalwa ngokubanda kunye nobukhulu obufanayo bodonga lombhobho wensimbi);Ibhetyebhetye ngakumbi kuneentsimbi eziqhelekileyo, iqinile...Funda ngokugqithisileyo -

Umgangatho wokugaya umphezulu wenkqubo yobhedu yokuqengqeleka eshushu

Inkqubo eshushu yokuqengqeleka komcu wobhedu yinkqubo yokuqala yokufudumeza kwe-ingot engapheliyo, ukuqengqeleka okushushu kunye nokuqengqeleka okubandayo, kwaye ikwayinkqubo ephambili yolawulo lomgangatho womphezulu womcwe.Kwinqanaba lokufudumala, i-atmospheric kwisithando somlilo, ubushushu, ixesha lokufudumeza kunye nomgangatho we-co ...Funda ngokugqithisileyo -

Ukusetyenziswa kunye nokunyangwa kweekhemikhali zokupholisa iphepha lobhedu

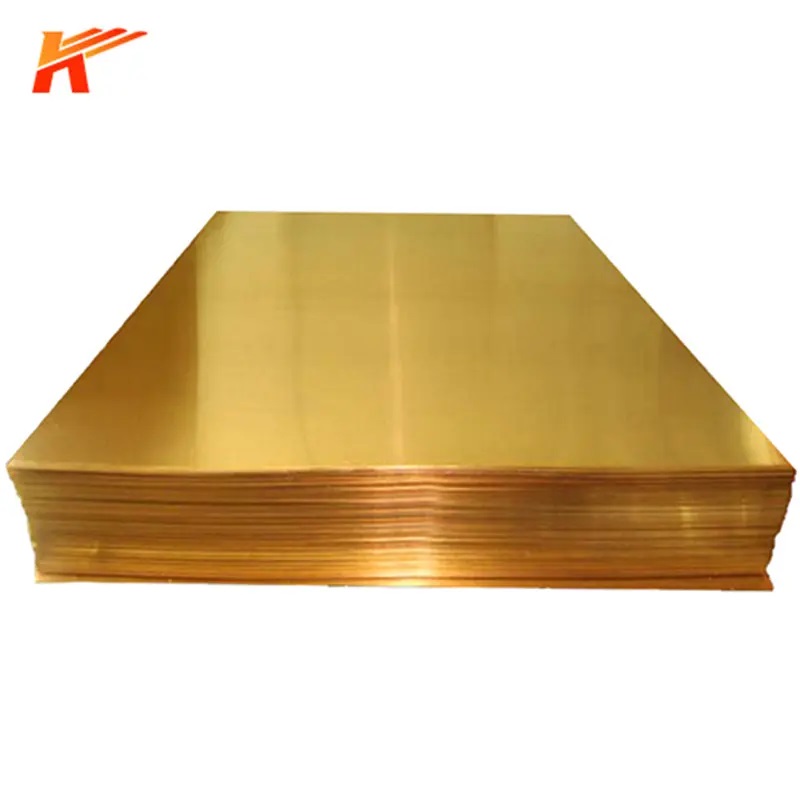

Ubhedu lunokucutshungulwa kwiphepha lobhedu, ucingo lobhedu, njl., lusetyenziswe kuzo zonke iikona zobomi.Okokuqala, inokusetyenziswa kwishishini le-HNA.Kuba ipleyiti yobhedu nokuba ibanda okanye ishushu, inokusebenza kakuhle kakhulu.Ke isetyenziswa ngokubanzi kwiindawo zokusetyenzwa kwezinye izixhobo zaseLwandle ...Funda ngokugqithisileyo -

Ubunzima kwi-welding copper strips

Umtya wobhedu unombane olungileyo kunye ne-thermal conductivity, kodwa kusekho iingxaki ezininzi ezinzima kwinkqubo ye-welding.I-thermal conductivity yebhanti yobhedu ebomvu inkulu kakhulu kuneyentsimbi.Ukushisa kwe-Welding kunokwenzeka ukuba kulahleke, ngakumbi kunokubangela uxinzelelo olugqithisileyo lwangaphakathi, ...Funda ngokugqithisileyo -

Ukucubungula iteknoloji kunye nokusetyenziswa komcu wobhedu

Itekhnoloji yolwazi isandulela setekhnoloji ephezulu.Umkhwa ophambili wophuhliso lwekhompyuter ukhawuleza kwaye uzinzile ukuhanjiswa kwedatha, i-bandwidth kunye nokusetyenziswa kwamandla aphantsi.Kwikhompyutheni idinga inani elikhulu le-alloy strip yobhedu entwasahlobo, i-contactor, i-switch kunye nezinye iindawo ezi-elastic.Inqaku elikhulu ...Funda ngokugqithisileyo -

Reverse iteknoloji ye-extrusion kunye nomgaqo wokukhetha wephepha lobhedu

Ngophuhliso loqoqosho kunye nenzululwazi kunye nobuchwepheshe, iimfuno zomgangatho wemveliso extruded ziphezulu nangaphezulu, kwaye ezinye iimfuno ezikhethekileyo zibekwe phambili kwezinye iinkalo, ezikhuthaza uphuhliso olukhawulezayo lobhedu sheet reverse extrusion ubuchwepheshe.Uhlobo olutsha lwe-reverse ex...Funda ngokugqithisileyo -

Ukusetyenziswa komcu wobhedu kunye nokusetyenzwa

I-Brass strip yi-conductor ende yee-rectangular okanye i-chamfered sections ezenziwe ngobhedu, ezisetyenziselwa ukuthwala okwangoku kwiisekethe kunye nokudibanisa izixhobo zombane.Ngenxa yokuba ubhedu lungcono kune-aluminiyam ekuqhubeni umbane, i-bras strip isetyenziswe ngokubanzi kwizixhobo zombane, ngakumbi kumandla ...Funda ngokugqithisileyo -

Inkqubo yokugaya iphepha lobhedu

Iphepha le-Brass polishing libhekisela ekukhethweni kokubonakaliswa kwesiphumo, ukwenzela ukuba umphezulu wephepha lobhedu ungabikho kwinqanaba eligudileyo, lenze libe likhulu ngakumbi, lilinganisa ubuso besisombululo.Isitshixo sokupholisha ubhedu kukusebenzisa iindlela ezimbini: indlela yeekhemikhali zoomatshini kunye nefizikhi...Funda ngokugqithisileyo -

Itekhnoloji ye-silicon yobhedu

Inkqubo yokuphosa ye-silicon yobhedu: ukunyibilika kunye nokugalela.Ubhedu lwesilicon lunyibilikiswa kwiziko lokungenisa iasidi.Intlawulo kufuneka ifudunyezwe kwi-150 ~ 200 ℃ ngaphambi kokuba ifakwe kwiziko, kwaye ubhedu lwe-electrolytic kufuneka lucocwe, losiwe kwiqondo lokushisa eliphezulu kwaye lucocwe ngokupheleleyo ...Funda ngokugqithisileyo -

Indlela yokulungiselela kunye nokusetyenziswa kobhedu olucocekileyo oluphezulu

Ubhedu olucocekileyo oluphezulu lubhekisela ekuhlambulukeni kobhedu lufikelela kwi-99.999% okanye ngaphezulu kwe-99.9999%, kunye neempawu zayo ezahlukeneyo zomzimba ziphuculwe kakhulu kunezo ezinobunyulu obuphantsi.Ubhedu lunombane kunye ne-thermal conductivity elungileyo, kwaye luthambile kwaye luthambile.Ubhedu luqhele ukusetyenziswa ukwenza iingcingo ...Funda ngokugqithisileyo -

Ukusetyenziswa kunye noLawulo loMgangatho weeNgxobhozo zeBrass

Iintsimbi zobhedu zizinto ezimile okwentonga ezenziwe ngobhedu kunye ne-zinc alloys, ezithiywe ngombala wazo otyheli.I-Brass enomxholo wobhedu we-56% ukuya kwi-68% inendawo yokunyibilika ye-934 ukuya kwi-967 degrees.I-Brass ineempawu ezilungileyo zoomatshini kunye nokumelana nokunxiba, kwaye ingasetyenziselwa ukwenza izixhobo ezichanekileyo, inqanawa ...Funda ngokugqithisileyo -

Ulwazi lweengcali kwiindlela zokugcina iintonga zobhedu

Ulwazi lweengcali kwiindlela zokugcina iintonga zobhedu 1. Kufuneka simise indawo yokugcina impahla.Ubushushu bokubeka ubhedu luyi-15 ukuya kuma-35 degrees phakathi.Intonga yobhedu engenayo ioksijini kunye nocingo lwentsimbi oluzoba ipleyiti yobhedu kufuneka iwudlule umthombo wamanzi.Ithini indlela yokugcina intonga yobhedu...Funda ngokugqithisileyo